- Measure deformations and misalignments

- Detect cracks, deflections, or settlement

- Generate structural profiles and as-built models

- Plan retrofitting or repair work with precision

Laser scanning delivers results with millimetre precision, detecting structural changes that are invisible to the human eye.

✔️ Non-Invasive & Safe

The scanning process is fully non-destructive, ideal for heritage buildings, occupied structures, or sensitive environments.

✔️ Time-Saving

What used to take days with manual measurements now takes just hours, speeding up both inspection and project planning.

✔️ Data-Driven Reports

We generate point clouds, heat maps, and 3D models that engineers can use for structural analysis, BIM, and repair design.

- Assessing building settlement or leaning

- Mapping cracks and concrete defects

- Verifying as-built conditionsbefore retrofitting

- Monitoring movement over time(structural health monitoring)

- Supporting heritage conservationwith digital records

- Root causes of structural problems

- Risk zones for future failure

- Most effective repair and strengthening methods

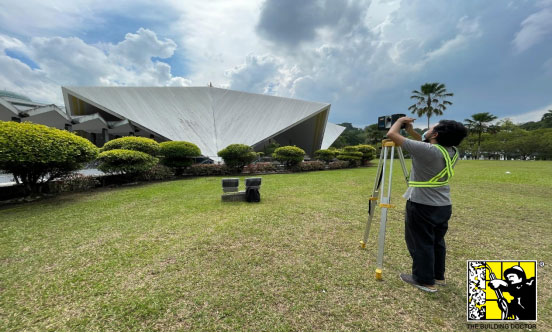

- Captured the full façade layout in high resolution

- Detected subtle column shifts and joint misalignment

- Recommended CFRP strengthening and crack injection

- Verified repairs post-work using a second scan

1. What is the difference between 3D laser scanning and traditional inspection?

Traditional inspections rely on visual assessment and manual measurements, which can be subjective and limited. 3D laser scanning provides highly accurate, digital models of your structure with millimetre precision—ideal for detecting movement, misalignment, and hidden defects.

2. Is 3D scanning suitable for all building types?

Yes. It’s effective for:

- High-rise commercial buildings

- Industrial plants

- Heritage structures

- Bridges and podium decks

- Basement and foundation analysis

3. How long does a typical 3D laser scanning session take?

A scan may take several hours to a whole day, depending on the size and scope of the structure. Data processing and report generation usually follow within 7-14 working days.

4. Does 3D scanning replace the need for engineers?

No—it enhances their work. The scan supports structural engineers by providing accurate visuals and data to make more informed decisions about diagnosis, design, and repair strategies.

5. Can 3D scans be used for before-and-after repair comparison?

Absolutely. We often perform a second scan post-repair to confirm structural alignment, surface corrections, or crack closure—giving clients a clear “before vs after” visual.

6. How much does 3D scanning cost in Malaysia?

Costs vary by building size, complexity, and data usage. We offer competitive packages for scanning, diagnosis, and bundled repair services. Contact us for a quotation based on your project needs.

👷♂️ Work Smarter, Not Just Harder

In today’s world, advanced diagnostics lead to smarter repairs. Whether you’re a consultant, developer, or asset manager, 3D laser scanning provides clarity, accuracy, and confidence.

📧 Email us: structuralrepairs@gmail.com

🌐 Visit: https://structuralrepairs.com.my

📞 Whatsapp: +60 12-334 9113

📍 Based in Kuala Lumpur, serving all of Malaysia